[The power of LVTC] LVTC teacher invented superb sheet metal part detector which takes two seconds only to inspect a sheet metal part -- Intelligent Auto Sheet Metal Parts Visual Detection System helps to improve efficiency and effectiveness for enterprises

News from News Network (Written by Shi Yudan from Party Committee Propaganda Department; photography by Wang Fuchun from College of Mechanical and Electrical Engineering, Wei Renzu from Students News Agency and Zhang Yuxin from Scientific Research Office) “We'd like to meet with some hard nuts, so that we can manage to work them out and turn them into our core technologies.” -- such an answer with unique LVTC characteristics was given by Liang Yun, a teacher from our College of Mechanical and Electrical Engineering, in response to the questions of numerous enterprises on the technical presentation of application of auto sheet metal parts visual inspection system held by Procurement Center of Liuzhou Wuling Automobile Industry Co., Ltd. in a hotel in Liujiang District at noon on June 20, 2018. Liang Yun is exactly the inventor of the system in question.

“Will it be possible to inspect 1000 pieces in one hour?” “Will it support some more flexible inspections?”... After Liang Yun has introduced the product to the leaders from over 20 auto parts makers, they raised their questions one after another and sometimes at once, creating a hot atmosphere.

It was said that the manual inspection of each sheet metal part took 50 seconds, while with our system the inspection ("machine inspection" hereinafter) needed 2 seconds only; with manual inspection 5 persons were required, and with machine inspection, 1 person only; several processes that were needed for manual inspection was cut to one step; 6-8 hours previously needed for inspecting 1000 parts was reduced to 3 hours with machine inspection; 30-40 man-hours needed for manual inspection was reduced to 3 man-hours... These substantial changes almost made our system an instant hit in the auto industry. Now the invention has transformed into a product and put on trial by an enterprise. It is believed to have great market potential and expected to perform well.

This invention is an outcome made by LVTC teachers through technical research in our school-enterprise cooperation, which eventually benefited the society. As an opportunity for communication and exchange, school-enterprise cooperation brings forth new ideas and a brand-new field. The Intelligent Auto Sheet Metal Parts Visual Detection System developed by Liang Yun and his maintenance & management team is such an example of successful research and trial-production achieved in the cooperation between school and enterprise. But for Liang Yun, this is only one among the 180 enterprise projects he has been engaged in.

Technical research for enterprises is the best way to test a teacher's ability and strength

Liang Yuan and his team began to put themselves into enterprise projects since 2004. So far, they've carried out a real deal of over 180 projects to reduce unnecessary burden and increase efficiency of companies. In 2017, they developed intelligent automotive air-conditioning test bed for Liuzhou Jinrun Auto Parts Co., Ltd., which functioned properly and greatly improved the company's efficiency. Before using the product, 1000 AC units took 8 hours for 5 persons to inspect; and with the intelligent test bed, only 1 person * 3 hours will be needed for the same work load! By largely increasing both efficiency and accuracy, and reducing the labor costs at the same time, the invention was highly praised by the company.

In 2015, they cooperated with Dongfeng Liuzhou Motor Co., Ltd. in the R&D of the automatic robot welding system for chassis beam of Fengxing commercial vehicles. The system was then put into production in 2016. The quality of manual welding was unstable. With the automatic welding system, the qualification ratio was raised to nearly 100%, over 15 times that of manual welding. So was the improvement of work efficiency. The company was satisfied beyond measure.

So far, the team has transformed/developed a total of over 180 sets of detection equipment for enterprises, which involves project funds of more than CNY 23 million. It not only solved a great amount of technology challenges for those businesses, but also significantly promoted the reliability, production efficiency and economic efficiency of the production facilities of local companies.

Among these results, the Intelligent Auto Sheet Metal Parts Visual Detection System is a latest high-technology product with broad prospects for application.

Server enterprises with technological innovations

In March 2017, an auto industry insider from the Supplier Quality Office of Guangxi Automotive Group discussed with Liang Yun a long-standing technical problem, i.e. currently manual inspection is widely adopted in the industry for auto body sheet metal parts. The amount of inspection items for each part ranges from a dozen to several dozens. The great number of products results in heavy work load, which, together with the repetitiveness of the operations, makes the workers tired and therefore caused inspection errors and omissions. Any unqualified product that is allowed in the successive process like welding, coating and even assembly will bring huge economic losses to the auto maker and parts plant.

So the insider asked Liang: to solve this problem, can you invent an auto body sheet metal part inspection system to make our work more efficient and the product more reliable?

With that target in mind, Liang Yun and his maintenance & management team devoted themselves into the related technical research. The team comprises of excellent graduates from LVTC. When they were studying in the college, they had participated in various skills competitions and won honors. Long Cairong and Lin Yuqiang graduated from NC equipment application and maintenance major in 2013, for example, have been working in the team on different projects, and greatly improved their comprehensive skills and overall capabilities consequently. The participated in the skills competition and won awards; and in 2016, they were granted the “May 1st Labor Medal” honor of Guangxi Province, becoming the most capable assistants of Liang Yun. They said, “If not felt ourselves were making progress working here, we would not stayed here for so long.” In our interview with Mr. Liang we felt he was always worried that someone would poach the two from him. He even said, "You can write about them, but better not mention them by names." We couldn't help wondering whether the students know how their teacher cherishes them so much!

R&D and trial production of new products are where the interest of Long and Lin lies in. Please follow the news column of LVTC's website for more about the two talents.

What is a sheet metal part?

Let's get to konw first what is a sheet metal part.

Sheet metal part is an essential part of auto body. The body of each automobile is made of hundreds of sheet metal parts in various types welded together. Liuzhou, as one of the five automotive cities in China, outputs more than 2,300,000 autos per year, and therefore has a large demand for sheet metal parts.

As a high-tech product, an automobile consists of various components. Automobile manufacturing is the source promoting a great many of downstream supporting enterprises, with a lot of job opportunities created therefrom. Developed countries had the automobile industry started earlier than China, and they also have more advanced auto-making technologies than China. As the process of globalization and China's opening-up is getting accelerated, a lot of foreign auto parts enterprises have got in Liuzhou to hold the market of many core auto parts, such as auto steering system, trip computers, interior parts, seats, etc.

However, auto sheet metal parts production, as a labor-intensive, low-profit industry, remains an uncultivated land beyond their reach. All sheet metal parts required in Liuzhou are being produced by local companies. Quality control is a vital step in the production of sheet metal parts.

Ideas: utilizing visual system in sheet metal part inspection

When you drive to work or home, the automatic detection system mounted at the gate scans your license plate to read the number and then allows you in. That is an application of visual technologies in real life. As the economic society moves forward, visual technologies will be widely adopted in different fields.

Machine visual technology is an interdiscipline that covers artificial intelligence, neurobiology, psychophysics, computer science, image processing, pattern recognition and many other areas. Machine vision is mainly used to simulate human vision with computers, so as to collect information from images of objective realities, then process such information to get it understood, and ultimately use it for actual detection, measurement and control. The basic features of machine visual technologies are fast speed, huge amount of information, and multi-function. Due to these advantages, the R&D team plans to apply the visual technologies in the inspection of auto sheet metal parts, so as to eliminate the high error rate in the inspection.

The 1st generation product was amazing

In March 2017, the R&D team discussed with senior officials of Guangxi Automobile Group Wuling Company. Their ideas were welcomed. Under the support of the leaders of the LVTC and the School, the team carried out tests with the prototype machine. In July, the "automatic sorting system for auto sheet metal part visual inspection" (1st generation) was successfully produced as a trial. The 1st generation prototype started from a high level. It came with a robot that could automatically load/unload, identify and sort workpieces. It is learned that more than one minute is needed to inspect a sheet metal part manually, while with the system, only 15 seconds is needed. This is a leading high-tech innovation not only in Guangxi but also in the whole country.

In August 2017, in China-ASEAN Vocational Education Exhibition, the system was highly praised by participants from all sectors. In September, they joined "Guangxi Industrial Innovation Contest" with the 1st generation product, which stood out of 300+ products of the Region, entered the final as the Top 4 products in the semifinal, and won the Third Prize in the final, receiving a reward of CNY 50,000. Afterwards, the LVTC granted another CNY 10,000 as award for the invention. It was highly recognized by all walks of life. It was the only innovation presented by a college in Liuzhou in that contest and won an award.

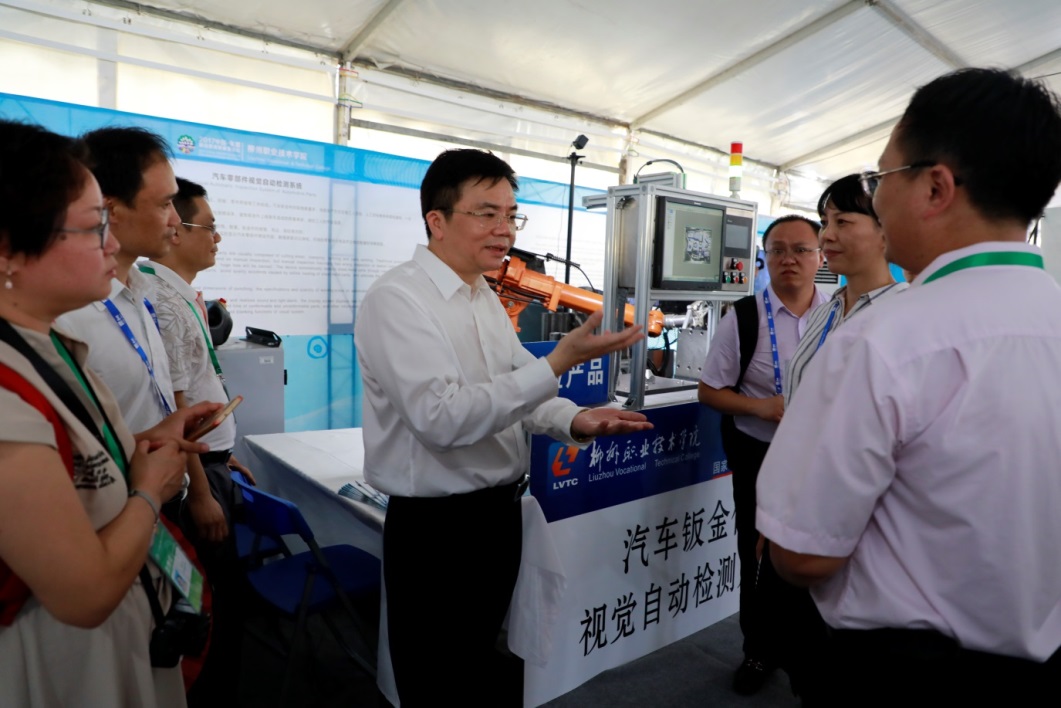

In 2017, in China-ASEAN Vocational Education Forum & Technological Innovation Exhibition, Huang Xiongbiao, Deputy Director of the Education Department of Guangxi Zhuang Autonomous Region, asked in detail how the students and teachers benefited while the system was developed, and how well it was applied in the production of companies. He said, "We have been keeping an eye on LVTC, and have higher requirements for LVTC. We need to meet the actual demands of the enterprises, and try to convert more patents into productivity."

Optimization and upgrading of the 2nd generation product: test a product in 2 seconds

After the contest, the team optimized the system.

After the discussion between Liujiang Jinrun Auto Parts Company and the team, a sales contract was entered into on the production of visual inspection system for the sheet metal parts to be used in Baojun 510 at the price of CNY 130,000 per unit. In February 2018, the products were handed over to the client. They have been running properly by far, and the team keeps collecting data for sheet metal parts and optimizing the performances. Formerly, it took 40-50 seconds for a worker to test a workpiece, but now the machine inspection for a workpiece takes only 2 seconds. Both the efficiency and reliability are improved, and 95% labor has been saved. Mr. Chen, a manager of Jinrun Company, said with emotion, "The system runs stably, and spared us 3 workers at least."

During the development process, the R&D team overcame a lot of technical challenges and made a lot of technical achievements. At present, those results are undergoing patents application.

Next, the R&D team plans to develop curriculum on visual technology and open them to students. They also prepare to set up Guangxi Visual Technology Application Center to further develop the technologies and promote their applications. According to Liang Yun, over ten enterprises showed their intention to cooperate on the technical presentation on June 20. Mr. Wei, manager of Yongxin Parts Company, said, "As long as it can cut our costs, guarantee the quality and improve the efficient, I definitely will buy it! It would be better to made into a production line, so that just one worker would be needed to control remotely."

Can his dream come true? Let us wait and see.

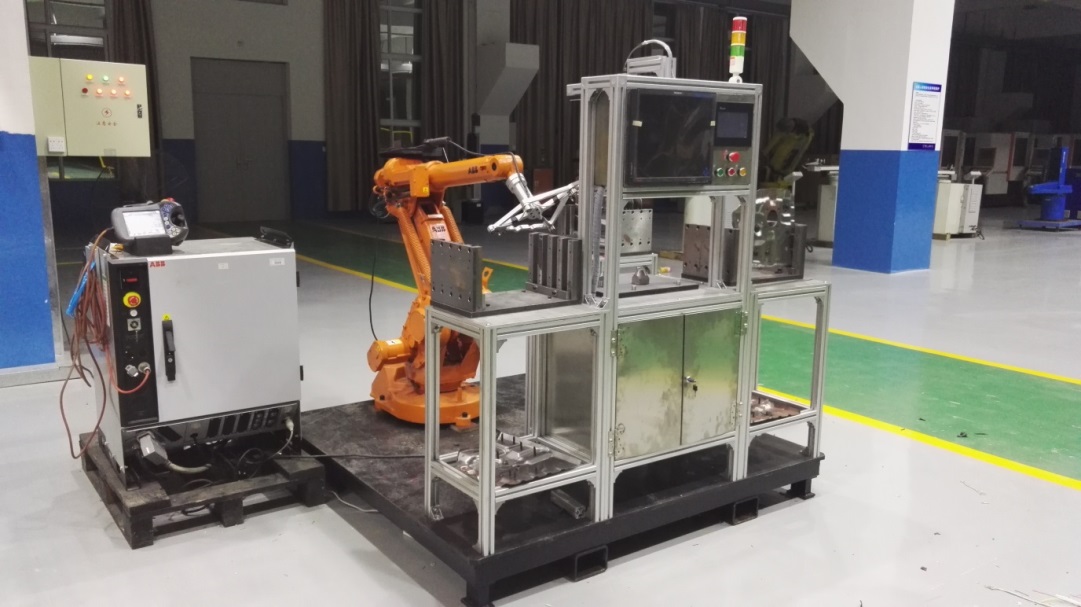

Intelligent Auto Sheet Metal Parts Visual Detection System

Huang Xiongbiao, Deputy Director of Guangxi Education Department, encouraged our teachers to convert more patents into productivity

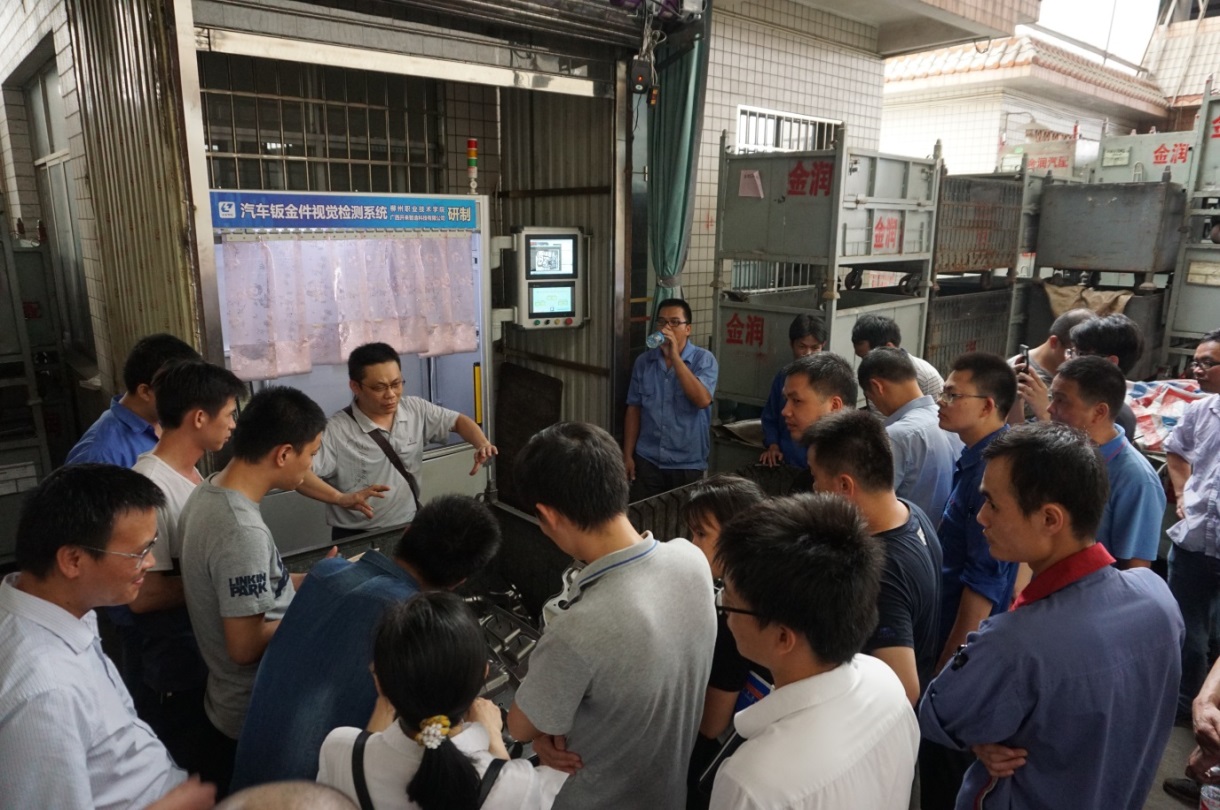

Liang Yun showed how the system works at Jinrun Auto Parts Company

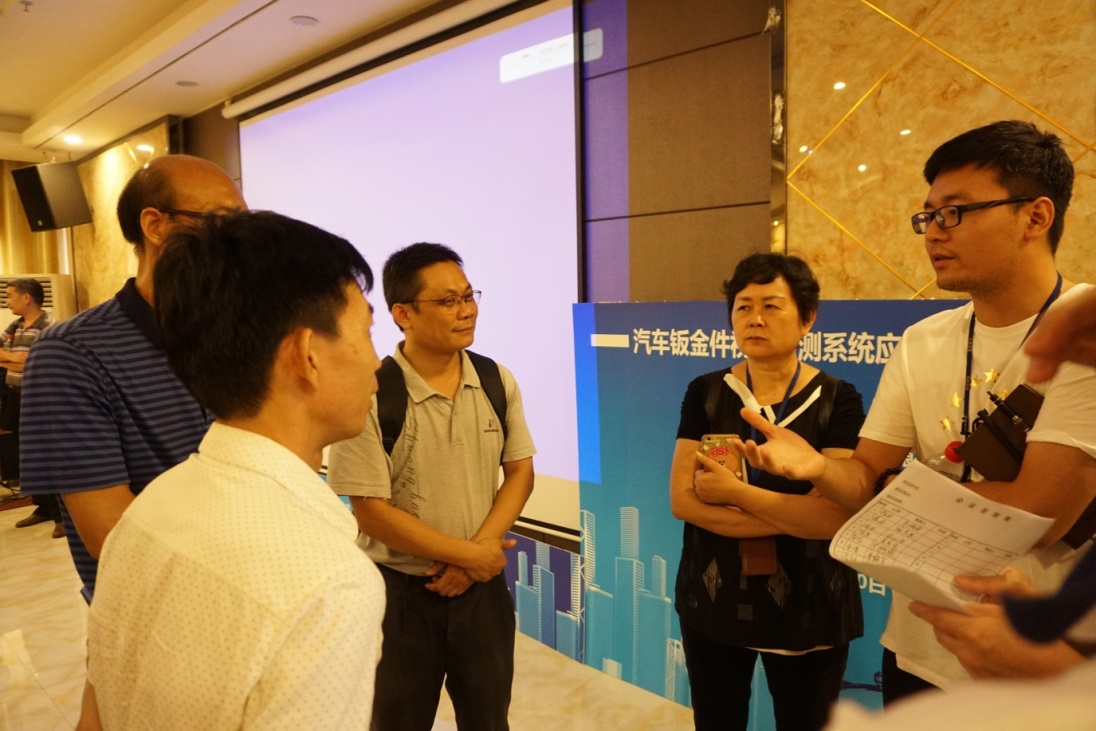

Representatives of the suppliers attended the Presentation on June 20, 2018

Liang Yun, teacher from College of Mechanical and Electrical Engineering, LVTC introduced the product

Supplier representatives were asking questions

After the meeting, enterprise representatives were reluctant to leave. They standed around Mr. Liang Yu to discuss with him enthusiastically